Engineering Practices Laboratory

| Lab Name | Area |

|---|---|

| Engineering Practices Laboratory | 300 m² |

List of Major Equipments

| S. No | Name of the Equipment | Quantity |

|---|---|---|

| 1 | Arc welding transformer with cables and holders | 5 |

| 2 | Welding booth with exhaust facility | 5 |

| 3 | Welding accessories like welding shield, chipping hammer, wire brush, etc. | 5 |

| 4 | Oxygen and acetylene gas cylinders, blow pipe and other welding outfit. | 2 |

| 5 | Centre lathe | 2 |

| 6 | Moulding table, foundry tools | 2 |

| 7 | Power Tool: Angle Grinder | 2 |

Computer Aided Drafting and Modelling Laboratory

| Lab Name | Area |

|---|---|

| Computer Aided Drafting and Modelling Laboratory | 300 m² |

List of Equipments & Amounts

| S. No | Name of the Equipment | Quantity Available |

|---|---|---|

| 1 | Pentium IV computer or better hardware, with suitable graphics facility | 30 |

| 2 | Licensed software for Drafting and Modelling | 30 |

| 3 | Laser Printer or Plotter to print / plot drawings | 2 |

Manufacturing Technology Lab – I

| Lab Name | Area |

|---|---|

| Manufacturing Technology Lab – I | 300 m² |

List of Major Equipments

| S. No | Name of the Equipment | Quantity Available |

|---|---|---|

| 1 | Centre Lathes | 7 |

| 2 | Horizontal Milling Machine | 1 |

| 3 | Shaper | 1 |

| 4 | Vertical Milling Machine | 1 |

Manufacturing Technology Laboratory - II

| Lab Name | Area |

|---|---|

| Manufacturing Technology Laboratory - II | 300 m² |

List of Major Equipments

| S. No | Name of the Equipment | Quantity Available |

|---|---|---|

| 1 | Turret and Capstan Lathes | 1 |

| 2 | Horizontal Milling Machine | 2 |

| 3 | Vertical Milling Machine | 1 |

| 4 | Surface Grinding Machine | 1 |

| 5 | Cylindrical Grinding Machine | 1 |

| 6 | Radial Drilling Machine | 1 |

| 7 | Lathe Tool Dynamometer | 1 |

| 8 | Milling Tool Dynamometer | 2 |

| 9 | Gear Hobbing Machine | 1 |

| 10 | Tool Makers Microscope | 1 |

| 11 | Gear Shaping machine | 1 |

| 12 | CNC Milling machine | 1 |

| 13 | CNC Lathe | 1 |

| 14 | Centerless grinding machine | 1 |

| 15 | Tool and cutter grinder | 1 |

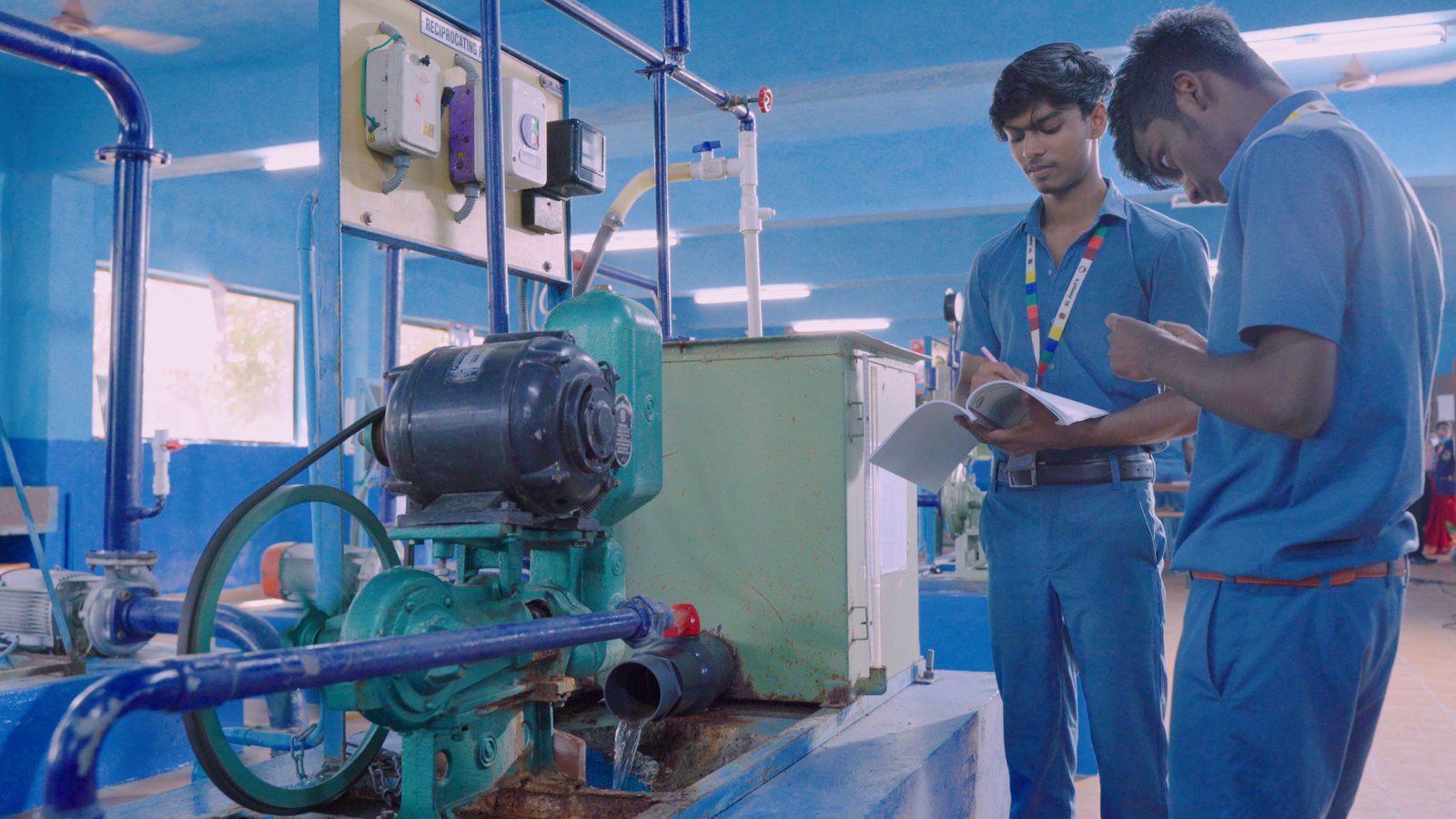

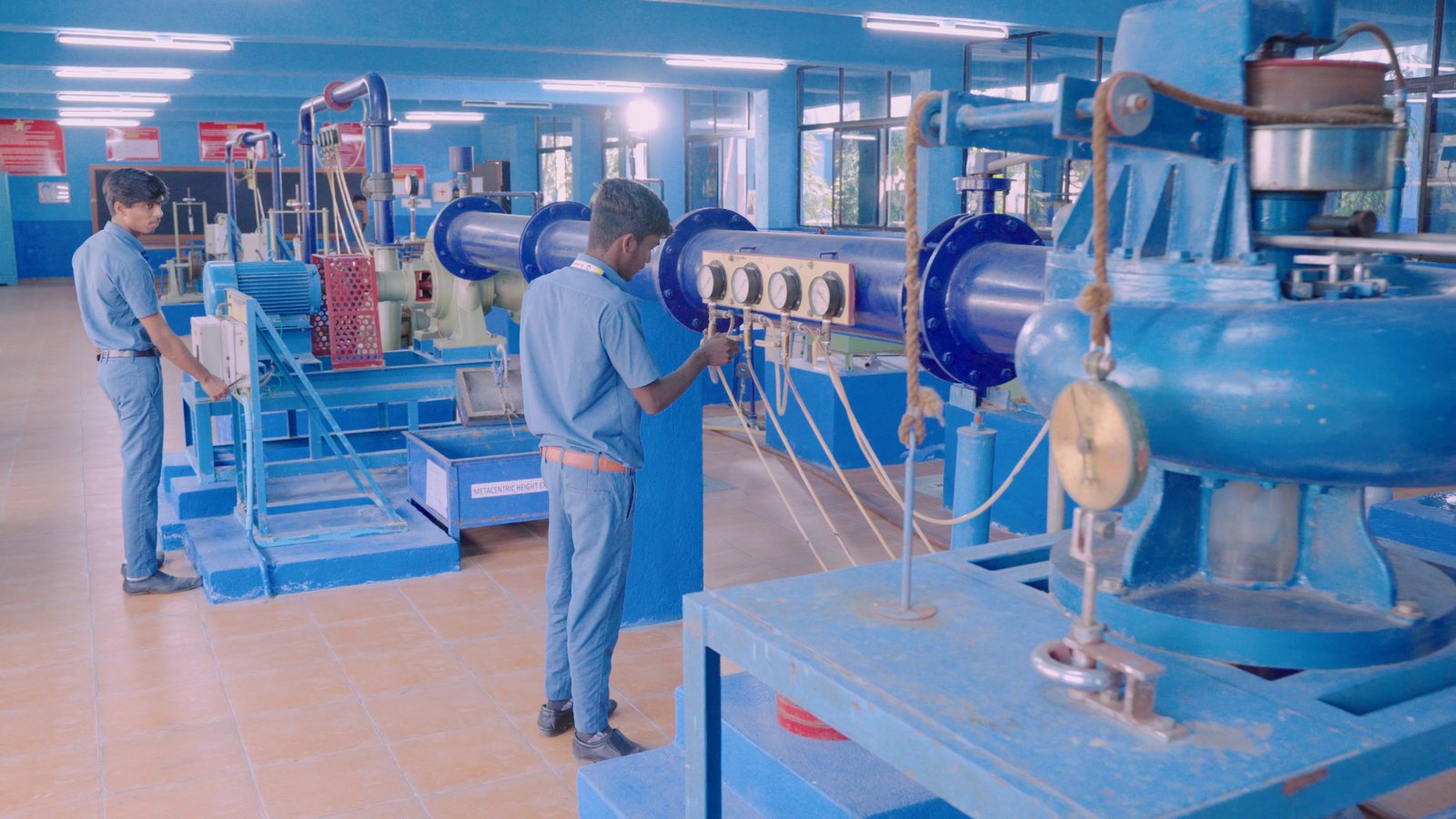

Fluid Mechanics and Machinery Laboratory

| Lab Name | Area |

|---|---|

| Fluid Mechanics and Machinery Laboratory | 300 m² |

List of Major Equipments

| S. No | Name of the Equipment | Quantity Available |

|---|---|---|

| 1 | Orifice meter setup | 1 |

| 2 | Venturi meter setup | 1 |

| 3 | Rotameter setup | 1 |

| 4 | Pipe Flow analysis setup | 1 |

| 5 | Centrifugal pump/submergible | 1 |

| 6 | Reciprocating pump setup | 1 |

| 7 | Gear pump setup | 1 |

| 8 | Pelton wheel setup | 1 |

| 9 | Francis turbine setup | 1 |

| 10 | Kaplan turbine setup | 1 |

Thermal Engineering Laboratory - I

| Lab Name | Area |

|---|---|

| Thermal Engineering Laboratory - I | 300 m² |

List of Major Equipments

| S. No | Name of the Equipment | Quantity Available |

|---|---|---|

| 1 | I.C Engine – 2 stroke and 4 stroke model | 1 |

| 2 | Apparatus for Flash and Fire Point | 1 |

| 3 | 4-stroke Diesel Engine with mechanical loading. | 1 |

| 4 | 4-stroke Diesel Engine with hydraulic loading. | 1 |

| 5 | 4-stroke Diesel Engine with electrical loading. | 1 |

| 6 | Multi-cylinder Petrol Engine | 1 |

| 7 | Single cylinder Petrol Engine | 1 |

| 8 | Data Acquisition system with any one of the above engines | 1 |

| 9 | Steam Boiler with turbine setup | 1 |

Thermal Engineering Laboratory - II

| Lab Name | Area |

|---|---|

| Thermal Engineering Laboratory - II | 300 m² |

List of Major Equipments

| S. No | Name of the Equipment | Quantity Available |

|---|---|---|

| 1 | Guarded plate apparatus | 1 |

| 2 | Lagged pipe apparatus | 1 |

| 3 | Natural convection-vertical cylinder apparatus | 1 |

| 4 | Forced convection inside tube apparatus | 1 |

| 5 | Composite wall apparatus | 1 |

| 6 | Thermal conductivity of insulating powder apparatus | 1 |

| 7 | Pin-fin apparatus | 1 |

| 8 | Stefan-Boltzmann apparatus | 1 |

| 9 | Emissivity measurement apparatus | 1 |

| 10 | Parallel/counter flow heat exchanger apparatus | 1 |

| 11 | Single/two stage reciprocating air compressor. | 1 |

| 12 | Refrigeration test rig | 1 |

| 13 | Air-conditioning test rig | 1 |

Strength of Materials Laboratory

| Lab Name | Area |

|---|---|

| Strength of Materials Laboratory | 150 m² |

List of Major Equipments

| S. No | Name of the Equipment | Quantity Available |

|---|---|---|

| 1 | Universal Tensile Testing machine with double shear attachment – 40 Ton | 1 |

| 2 | Torsion Testing Machine (60 NM Capacity) | 1 |

| 3 | Impact Testing Machine (300 J Capacity) | 1 |

| 4 | Brinell Hardness Testing Machine | 1 |

| 5 | Rockwell Hardness Testing Machine | 1 |

| 6 | Spring Testing Machine for tensile and compressive loads (2500 N)s | 1 |

| 7 | Metallurgical Microscopes | 3 |

| 8 | Muffle Furnace (800 °C) | 1 |

Dynamics Laboratory

| Lab Name | Area |

|---|---|

| Dynamics Laboratory | 150 m² |

List of Major Equipments

| S. No | Name of the Equipment | Quantity Available |

|---|---|---|

| 1 | Cam follower setup | 1 |

| 2 | Motorised gyroscope. | 1 |

| 3 | Governor apparatus - Watt, Porter, Proell and Hartnell governors. | 1 |

| 4 | Whirling of shaft apparatus. | 1 |

| 5 | Dynamic balancing machine. | 1 |

| 6 | Two rotor vibration setup. | 1 |

| 7 | Spring mass vibration system. | 1 |

| 8 | Torsional vibrationof single rotor system setup. | 1 |

| 9 | Gear Models. | 1 |

| 10 | Kinematic Models to study various mechanisms. | 1 |

| 11 | Turn table apparatus. | 1 |

| 12 | Transverse vibration setup of a) cantilever b) Free-Free beam c) Simply supported beam. | 1 |

Metrology and Measurements Laboratory

| Lab Name | Area |

|---|---|

| Metrology and Measurements Laboratory | 150 m² |

List of Major Equipments

| S. No | Name of the Equipment | Quantity Available |

|---|---|---|

| 1 | Micrometer | 5 |

| 2 | Vernier Caliper. | 5 |

| 3 | Vernier Height Gauge. | 2 |

| 4 | Vernier depth Gauge. | 2 |

| 5 | Slip Gauge Set. | 1 |

| 6 | Gear Tooth Vernier. | 1 |

| 7 | Sine Bar. | 1 |

| 8 | Floating Carriage micrometer. | 1 |

| 9 | Profile Projector/Tool Makers. | 1 |

| 10 | Microscope. | 1 |

| 11 | Mechanical/Electrical Comparator. | 1 |

| 12 | Autocollimator. | 1 |

| 13 | Temperature Measuring Setup. | 1 |

| 14 | Force Measuring Setup. | 1 |

| 15 | Torque Measuring Setup. | 1 |

| 16 | Surface Finish measuring equipment. | 1 |

| 17 | Bore gauge. | 1 |

| 18 | Telescope gauge. | 1 |

CAD / CAM Laboratory

| Lab Name | Area |

|---|---|

| CAD / CAM Laboratory | 100 m² |

List of Major Equipments

| S. No | Name of the Equipment | Quantity Available |

|---|---|---|

| 1 | Computer Server | 1 |

| 2 | Computer nodes or systems (High end CPU with atleast 1 GB main memory) networked to the server | 30 |

| 3 | Laser Printer | 1 |

| 4 | CNC Lathe | 1 |

| 5 | CNC milling machine | 1 |

| 6 | Any High end integrated modeling and manufacturing CAD / CAM software | 15 licenses |

| 7 | CAM Software for machining centre and turning centre (CNC Programming and tool path simulation for FANUC / Sinumeric and Heiden) | 15 licenses |

Simulation and Analysis Laboratory

| Lab Name | Area |

|---|---|

| Simulation and Analysis Laboratory | 100 m² |

List of Major Equipments

| S. No | Name of the Equipment | Quantity Available |

|---|---|---|

| 1 | Computer System(17” VGA Color Monitor,Pentium IV Processor,40 GB HDD,512 MB RAM) | 30 |

| 2 | Color Desk Jet Printer | 1 |

| 3 | Software Suitable Analysis software | 30 licenses |

| 4 | C / MATLAB | 5 licenses |

Mechatronics Laboratory

| Lab Name | Area |

|---|---|

| Mechatronics Laboratory | 150 m² |

List of Major Equipments

| S. No | Name of the Equipment | Quantity Available |

|---|---|---|

| 1 | Basic Pneumatic Trainer Kit with manual and electrical controls/ PLC Control | 1 |

| 2 | Basic Hydraulic Trainer Kit | 1 |

| 3 | Hydraulics and Pneumatics Systems Simulation Software / Automation studio sets | 10 |

| 4 | 8051 - Microcontroller kit with stepper motor and drive circuit sets | 2 |

| 5 | LAB VIEW software with Sensors to measure Pressure, Flow rate, direction, speed, velocity and force seats | 2 |